Introduction: Why the Right Equipment Matters

Think about it—how often do you hear stories of failed product launches due to issues with encapsulation? It’s a real headache in the industry, raising the question: what can be done to ensure smoother operations? A softgel encapsulation machine can be the game-changer you didn’t know you needed. With the right machinery, you can mitigate those frustrating failures and enhance overall efficiency.

Body: Bridging the Gap in Encapsulation Technology

Traditional Solution Flaws

Many companies still rely on outdated methods for softgel production, facing challenges like inconsistent capsule sizes and subpar biocompatibility. These traditional methods often lead to significant waste and higher costs—not exactly ideal, right? It’s essential to recognize that these flaws not only slow down your production but also impact your bottom line.

New Technology Principles

Enter advanced softgel encapsulation machines that utilize state-of-the-art technology. These machines, equipped with smart sensors and adjustable parameters, can create capsules with precision—think about less scrappage and better quality assurance. Isn’t it a tad comforting to know that there’s tech out there that actually addresses the most annoying issues in the industry?

Quantified User Benefits

The perks of investing in a new machine are pretty compelling. Users report up to a 30% increase in production rates, along with improved formulation consistency. No more second-guessing your output or stressing over compliance; a quality softgel encapsulation machine can let you sleep easier at night.

Conclusion: Three Metrics You Can’t Ignore

So, if you’re on the hunt for an upgrade, always verify these three metrics when choosing solutions: ① efficiency of production ② quality assurance protocols ③ biocompatibility factors. These will not only save you headaches down the road but will also aid you in identifying the best machinery for your needs.

Delving into Softgel Capsule Filling Machines

Let’s take a moment to focus on softgel capsule filling machines. You might wonder why you should even care about them. Well, if you’re serious about streamlining your operations, investing in a reliable softgel capsule filling machine can seriously boost your production line. These machines help in the seamless filling of capsules, which is crucial for ensuring that your product meets regulatory standards. Plus, with the latest models, you’re looking at enhanced automation and less labor costs, which everyone can appreciate.

Understanding Softgel Encapsulation Machine Manufacturers

Now let’s talk about softgel encapsulation machine manufacturers. It’s super important to choose wisely in this space. After all, not all manufacturers offer the same quality standards or support. Reliable softgel encapsulation machine manufacturers should be your go-to when considering new equipment. They typically provide comprehensive technical assistance and readily available spare parts, which can significantly lower maintenance costs and downtime.

Wrapping it Up with Brand Recommendations

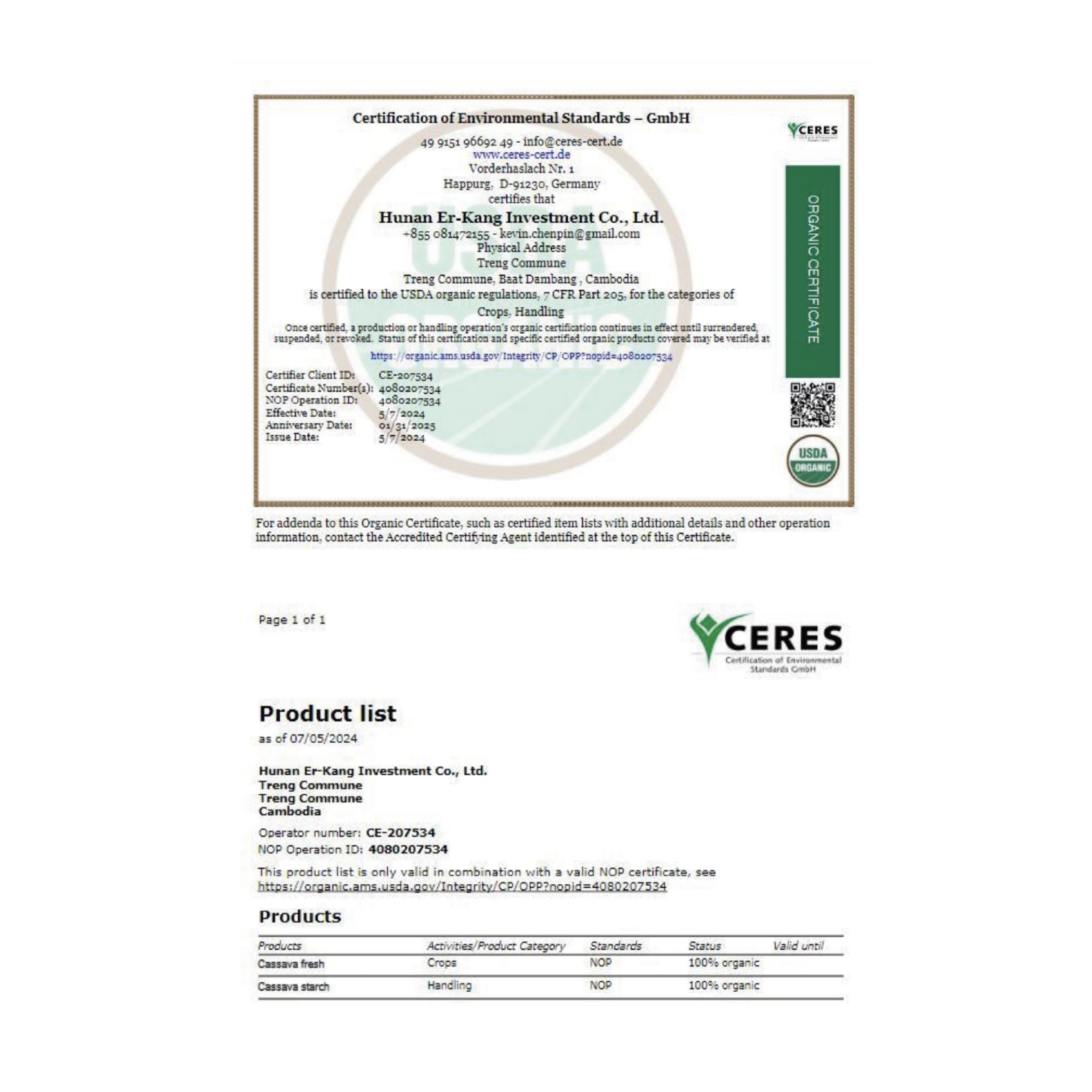

In summary, whether you’re tackling the nuances of softgel production or selecting the right equipment, it’s crucial to prioritize quality. Consider choosing a well-respected brand like Erkang—they’ve got solid supply advantages that can support your business needs. Investing in good manufacturing and machinery not only improves your products but also gives you peace of mind as you operate in this competitive landscape.