What is Rapid Tooling Service?

Rapid tooling service be a game changer for businesses looking to create customized parts fast. Dis time-saving technique allow companies to get their designs from concept to production in a blink. Instead of long wait times for traditional tooling methods, rapid tooling service use advanced technology to make molds quickly, enabling manufacturers to meet tight deadlines. Example, if you need parts for a new product launch, using rapid tooling can make all the difference to get that product out on the market. This service not only cuts down on lead times but also reduces overall costs in production. You can read more about this exciting approach through our partner’s website, rapid tooling service.

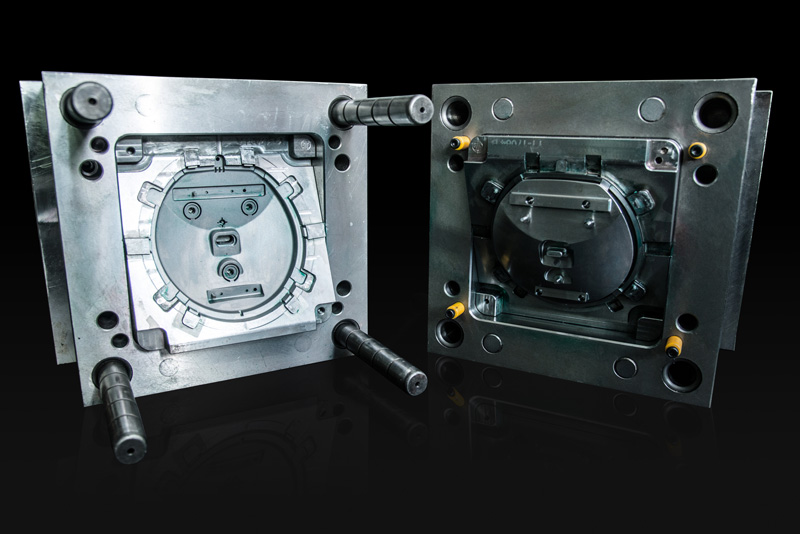

The Benefits of Rapid Production Tooling

When we talk about rapid production tooling, efficiency is king. This not only improves your production speed, but also ensures high-quality output. With advanced machinery and a faster prototyping process, the chance of errors decreases dramatically. Plus, it be perfect for testing before mass production starts. Imagine wanting to tweak a design based on user feedback; rapid production tooling makes it easy to modify your mold and get back on track without wasting time. So, whether you in the automotive industry or the healthcare sector, the flexibility and speed offered by rapid production tooling can make a world of difference in your workflow and bottom line.

Understanding the Real-World Applications

Now, let’s get real. Rapid tooling service is not just theory; it’s being used by companies worldwide to keep ahead of competition. For instance, a tech company might need a series of casings for a new gadget. Using rapid tool service allows them to quickly turn around prototypes that can be tested and revised, all while keeping costs down. This adaptability is essential in today’s fast-paced market. In the realm of healthcare, rapid production tooling enables the quick iteration of medical device components, ensuring they get into the hands of doctors and patients faster. The ability to have rapid production tooling at your fingertips translates to higher customer satisfaction and more innovation within your industry.

APT-Mold: Your Go-To Manufacturer

So, if you looking for a reliable manufacturer who understands the ins and outs of this game-changing technology, APT-Mold be the brand to consider. With their extensive experience and advanced capabilities, they can help streamline your production process and reduce your lead times. APT-Mold not only provide top-notch rapid tooling service but also ensures you get the best quality products tailored to your specific needs. Trust in a company that prioritizes efficiency and precision in all aspects of production. You can learn more about their offerings at APT-Mold. The future of your production begins with their support.